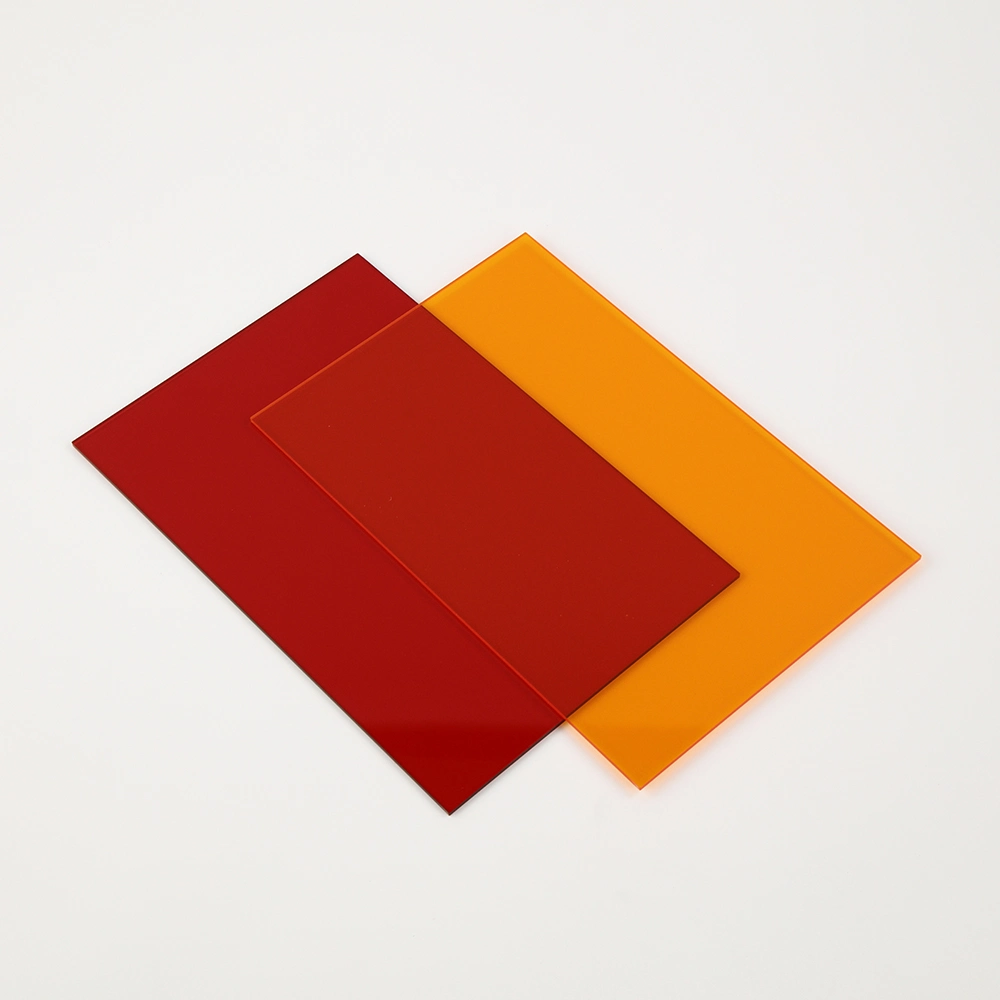

PMMA Sheets:

PMMA sheets are flat, transparent, and thermoplastic sheets made from polymethyl methacrylate (PMMA) resin, also known as acrylic. They are widely used in various industries such as automotive, electronics, architecture, and interior design.

PMMA sheets have several advantages over other materials, such as glass, due to their lightweight, high transparency, and excellent optical properties. They are also weather-resistant, impact-resistant, and have good chemical resistance, making them suitable for outdoor use.

PMMA sheets are often used in applications where high optical clarity is required, such as in skylights, signage, and display cases. They can also be easily machined, fabricated, and formed into different shapes, making them an excellent material for architectural and interior design projects.

PMMA sheets are a versatile material that offers excellent optical properties, durability, and ease of use, making them suitable for a wide range of applications.

Engineering Compounds:

Engineering compounds, also known as engineering plastics, are a type of plastic that is designed to have superior mechanical, thermal, and chemical properties compared to traditional commodity plastics. They are made by combining polymers with additives and fillers to create a material with specific characteristics that meet the demands of various engineering applications.

Engineering compounds offer a range of benefits, including high strength and stiffness, excellent dimensional stability, and resistance to heat, chemicals, and abrasion. They are used in a wide range of industries, including automotive, aerospace, electronics, and medical devices.

Examples of engineering compounds include acetal, nylon, polycarbonate, and ABS (Acrylonitrile Butadiene Styrene). Each type of engineering compound has its own set of properties and advantages, making them suitable for specific applications. For instance, acetal is known for its excellent dimensional stability and low friction, while nylon has high strength and toughness, and polycarbonate is known for its high impact resistance and optical clarity.

Overall, engineering compounds are an essential material in many industries due to their excellent mechanical and chemical properties, allowing them to meet the high demands of various engineering applications.

PC ABS Compounds:

PC-ABS compounds are a type of engineering plastic that is made by blending polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) polymers together. This combination of polymers results in a material with a unique set of properties that combines the strength, impact resistance, and heat resistance of PC with the flexibility and processability of ABS.

PC-ABS compounds are widely used in various industries, including automotive, electronics, and consumer goods. They offer excellent mechanical properties, such as high impact strength, good dimensional stability, and resistance to chemicals and UV radiation. Additionally, they have a high heat deflection temperature, making them suitable for applications that require high-temperature resistance.

Some common applications of PC-ABS compounds include automotive interior and exterior parts, electronic housings and enclosures, and appliances. They are also used in the production of 3D printed parts due to their ease of printing and ability to produce parts with high strength and durability.

On the whole, PC-ABS compounds are a versatile material that offers a unique combination of properties, making them suitable for a wide range of applications in various industries.

CATEGORY

- PC Sheets

- PMMA Sheets

- Engineering Compounds

- PC ABS Compounds

- SHEETS