We prioritize the highest standards of quality and reliability in our products. Each batch undergoes rigorous testing to meet industry specs and ensure consistent performance and durability.

We offer tailored solutions for PC Sheets, PMMA Sheets, and more — from custom colors to enhanced mechanical properties, we mold our materials to your needs.

Our engineers lead with innovation, investing in R&D to deliver advanced, reliable materials through cutting-edge technologies and deep technical know-how.

Welcome to Advanced Polymers Industrial Co. Ltd. (APIC), a premier manufacturer and innovator in high-performance plastic sheets and engineering compounds. Established in 2012, APIC began its journey with a strong focus on engineering and commodity compounds. In 2023, we expanded our expertise into plastic sheet manufacturing, further strengthening our position in the industry.

Headquartered in Jeddah, Saudi Arabia, APIC is strategically positioned to cater to the growing demands of both local and international markets. Our state-of-the-art manufacturing facilities, advanced R&D capabilities, and stringent quality control measures ensure that every product we deliver meets the highest standards of performance, durability, and reliability. With a commitment to excellence, cutting-edge technology, and sustainability, APIC continues to be a trusted name across various industries worldwide.

Know MoreEngineering compounds, also known as engineering plastics, are a type of plastic that is designed to have superior mechanical, thermal, and chemical properties compared to traditional commodity plastics. They are made by combining polymers with additives and fillers to create a material with specific characteristics that meet the demands of various engineering applications.

Engineering compounds offer a range of benefits, including high strength and stiffness, excellent dimensional stability, and resistance to heat, chemicals, and abrasion. They are used in a wide range of industries, including automotive, aerospace, electronics, and medical devices.

Examples of engineering compounds include acetal, nylon, polycarbonate, and ABS (Acrylonitrile Butadiene Styrene). Each type of engineering compound has its own set of properties and advantages, making them suitable for specific applications. For instance, acetal is known for its excellent dimensional stability and low friction, while nylon has high strength and toughness, and polycarbonate is known for its high impact resistance and optical clarity.

Overall, engineering compounds are an essential material in many industries due to their excellent mechanical and chemical properties, allowing them to meet the high demands of various engineering applications.

PC-ABS compounds are a type of engineering plastic that is made by blending polycarbonate (PC) and acrylonitrile butadiene styrene (ABS) polymers together. This combination of polymers results in a material with a unique set of properties that combines the strength, impact resistance, and heat resistance of PC with the flexibility and processability of ABS.

PC-ABS compounds are widely used in various industries, including automotive, electronics, and consumer goods. They offer excellent mechanical properties, such as high impact strength, good dimensional stability, and resistance to chemicals and UV radiation. Additionally, they have a high heat deflection temperature, making them suitable for applications that require high-temperature resistance.

Some common applications of PC-ABS compounds include automotive interior and exterior parts, electronic housings and enclosures, and appliances. They are also used in the production of 3D printed parts due to their ease of printing and ability to produce parts with high strength and durability.

On the whole, PC-ABS compounds are a versatile material that offers a unique combination of properties, making them suitable for a wide range of applications in various industries.

PMMA sheets are flat, transparent, and thermoplastic sheets made from polymethyl methacrylate (PMMA) resin, also known as acrylic. They are widely used in various industries such as automotive, electronics, architecture, and interior design.

PMMA sheets have several advantages over other materials, such as glass, due to their lightweight, high transparency, and excellent optical properties. They are also weather-resistant, impact-resistant, and have good chemical resistance, making them suitable for outdoor use.

PMMA sheets are often used in applications where high optical clarity is required, such as in skylights, signage, and display cases. They can also be easily machined, fabricated, and formed into different shapes, making them an excellent material for architectural and interior design projects.

PMMA sheets are a versatile material that offers excellent optical properties, durability, and ease of use, making them suitable for a wide range of applications.

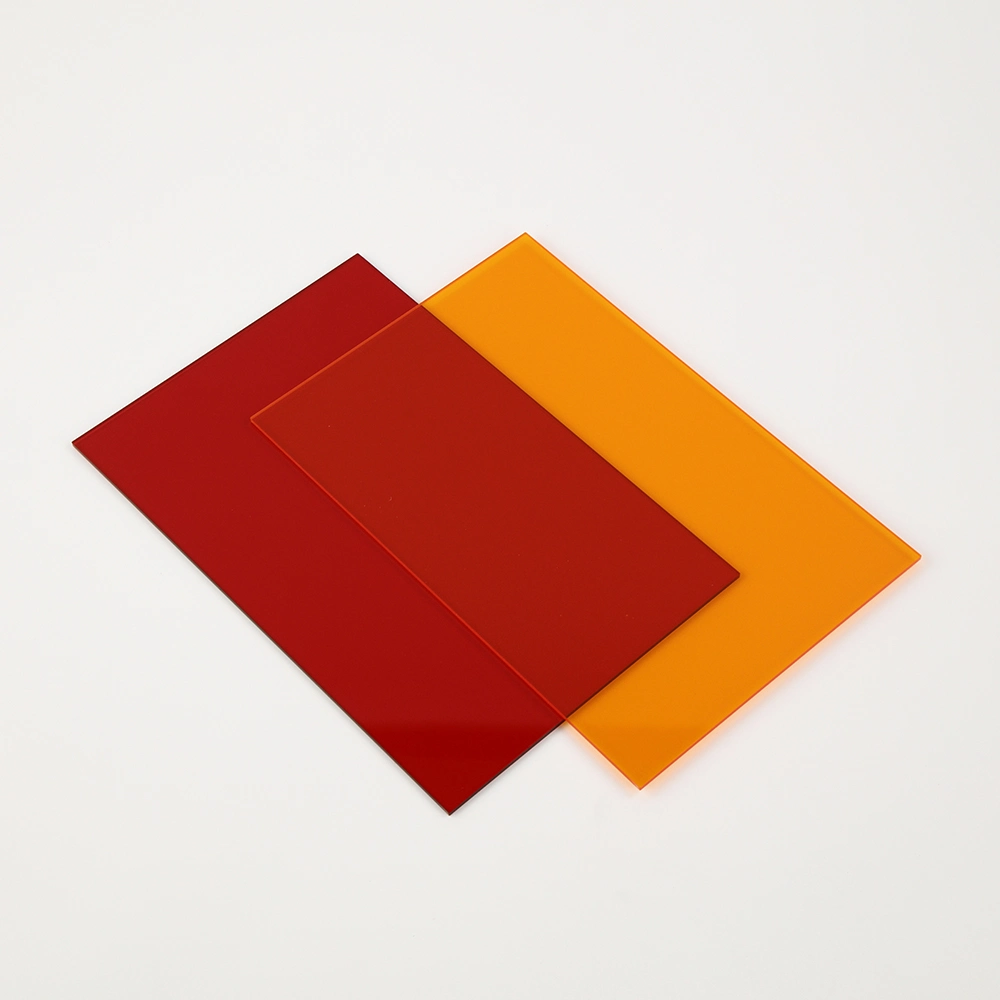

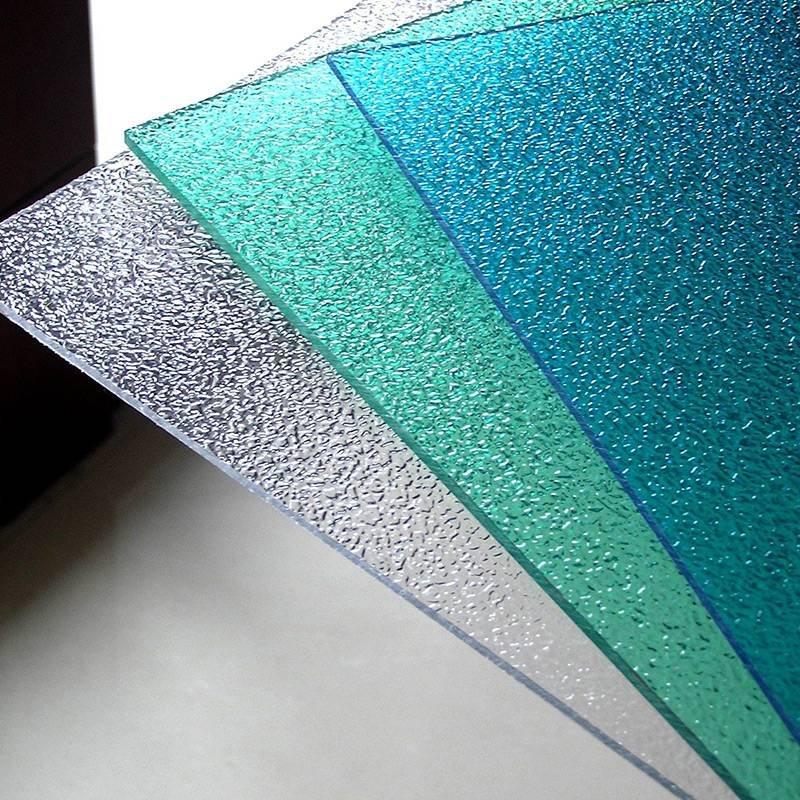

APIC Polycarbonate sheets are manufactured using only prime-quality virgin raw materials. Our product range includes a variety of colors and can be customized to meet specific customer requirements.

We also produce these sheets with different patterns, making them suitable for various applications.

APIC Polycarbonate sheets are available with UV coating, featuring co-extruded UV protection that allows them to be used in exterior applications exposed to UV light.

APIC manufactures high-quality PMMA sheets, offering a lightweight, shatter-resistant alternative to glass with superior optical clarity.

Available in various colors, thicknesses, and finishes, they are easy to cut, mold, and fabricate for diverse uses.

Widely utilized in construction, automotive, and advertising industries, APIC's PMMA sheets ensure long-lasting performance.

APIC manufactures high-quality and durable GPPS sheets, specializing in versatile solutions for various industries.

Their advanced manufacturing processes ensure superior clarity and strength, suitable for construction, packaging, and display applications.

Committed to innovation, they deliver reliable and cost-effective solutions.

Advanced Polymers Industrial Co. Ltd. (APIC) is a leading manufacturer of high-performance engineering compounds, offering superior mechanical, thermal, and chemical properties compared to traditional plastics.

These engineering compounds, including acetal, nylon, polycarbonate, and ABS, cater to industries such as automotive, aerospace, electronics, and medical devices.

APIC continues to be a trusted name in engineering plastics.

APIC specializes in widely used commodity plastics, including polypropylene (PP), polyethylene variants (HDPE, LDPE, LLDPE), polystyrene (PS), polyvinyl chloride (PVC), and PET.

With a state-of-the-art facility in Jeddah, Saudi Arabia, we ensure consistent quality and scalable production to meet global market demands.

As a trusted supplier, APIC remains committed to innovation, sustainability, and delivering tailored polymer solutions.

It is my pleasure to welcome you to Advanced Polymers Industrial Co. Ltd. (APIC), where innovation, superior quality, and sustainability form the foundation of everything we do. APIC was Established in 2012, we began our journey specializing in engineering compounds and, as of 2023, have expanded our expertise to include the manufacturing of plastic sheets, APIC has been dedicated to excellence in manufacturing high-performance plastic sheets and engineering compounds, serving industries across the globe. At APIC, delivering the best quality and ensuring customer satisfaction are at the core of our mission. We believe in building long-term partnerships by providing innovative, reliable, and high-performance solutions tailored to your evolving needs. As industries progress, we continuously strive to stay ahead, integrating cutting-edge technology and sustainable practices to contribute to a better, more resilient future. I extend my heartfelt gratitude to our customers, partners, and employees for their trust and unwavering support. Together, we will continue to grow, innovate, and shape a sustainable tomorrow.

Best Regards,

Wasim Ahmed Naik

Chairman & CEO, Advanced Polymers Industrial Co. Ltd. (APIC)

Hear What Our Customers Have to Say